By Colleen Acres

AgriNews Contributor

Most breeds of sheep grow wool. There are a few breeds though that are hair breeds and they shed, although not all shed completely.

Good animal husbandry requires annual shearing of wool breeds and cleaning up those non-shedders. It is a once-a-year ritual that most sheep and lamb farms arrange in spring or early summer. Some larger flocks that lamb out of season, will plan to have their pregnant ewes shorn approximately one month prior to lambing. The amount and quality of wool produced can be improved through good management, breeding and feeding practices. So even if wool is not a priority or focus of the farm, a good quality wool clip can add to farm returns when market prices are favourable.

In preparation for shearing, sheep producers need to book a qualified shearer well in advance. A listing of shearers can be found on the Canadian Cooperative Woolgrowers website and in their catalogue: www.wool.ca. An expert shearer using power equipment like barber clippers only larger, and they can shear a sheep in less than five minutes, rolling off the fleece in one piece.

Ensure that sheep are dry. If the weather is rainy the day before the shearer is coming, make sure the flock gets locked up inside under cover to ensure dry fleeces.

Have a level, clean area for the shearer that is well lit and has access to power. Many shearers like to use a couple sheets of plywood to shear on. Keep a broom handy to regularly clean off the shearing area between animals.

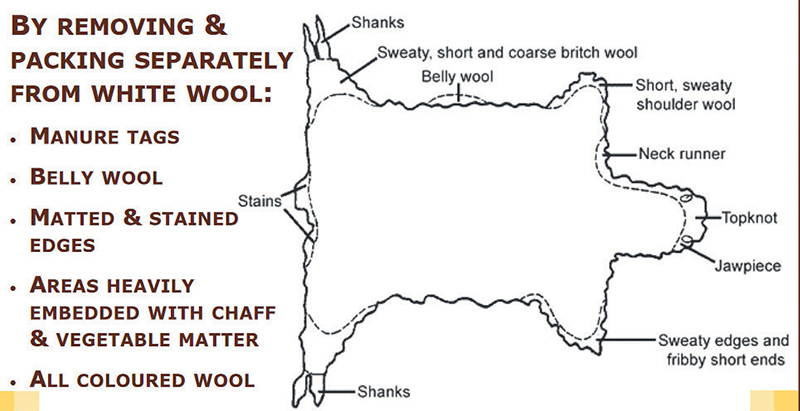

Have helpers to skirt fleeces and pack wool bags. Bags can be bought from the shearer or at CCWG. A skirting table is used to throw each individual fleece and remove any dirty tags or foreign matter and then fold the fleeces before packing into bags. See diagram attached. Belly wool should be kept out and packed into a separate bag. Dark fleece animals should be shorn separately and at the end to eliminate cross contamination of fibre colours.

Sheep are more comfortable when shorn on an empty stomach rather than a full one, so plan to withhold or reduce feed in advance of shearing time.

Sheep should be crowded tightly together for ease of access for the shearer. If you do not have a handling system or chute, a small catch pen kept full to limit chasing works.

Canada produces approximately 3 million pounds of wool annually. This is only a fraction of the total world production of wool, but Canadian wool is high in elasticity. This elasticity or springiness enables wool to retain its original shape. Canadian wool is blended with wool from other countries with less desirable characteristics. Since there is virtually no wool processing in this country, only ten percent of Canada’s production is sold here. Ninety per cent is exported to Britain, France, Germany, Spain, Japan, United States, China and India.

Most of the Canadian wool is collected centrally from across Canada in Carleton Place, Ontario where it is weighed, graded and sorted. Grading involves spreading out the raw wool, inspecting each fleece by hand and classifying it by the average diameter and length of the fibre, colour, lustre and crimp (tight, natural wave). From Carleton Place the graded grease wool is packed in 600 pd bales and shipped to world markets. Once sold, producers are paid based on how their fleece is graded.

World prices are currently very low, and stockpiles are growing as China is not buying. Also demand for textiles is significantly reduced with fewer demands for carpeting, clothing, etc as people work from home, refrain from travelling, etc. due to the pandemic. More domestic processing and ability to fill local demand for craftspeople would be welcomed. Also developing local processing for blankets, pillows, comforters and even insulation batts needs to be a higher priority.

For more information on Canadian wool and to find local producers selling wool products or local wool processing options go to www.wool.ca or https://www.ontariosheep.org/wool.