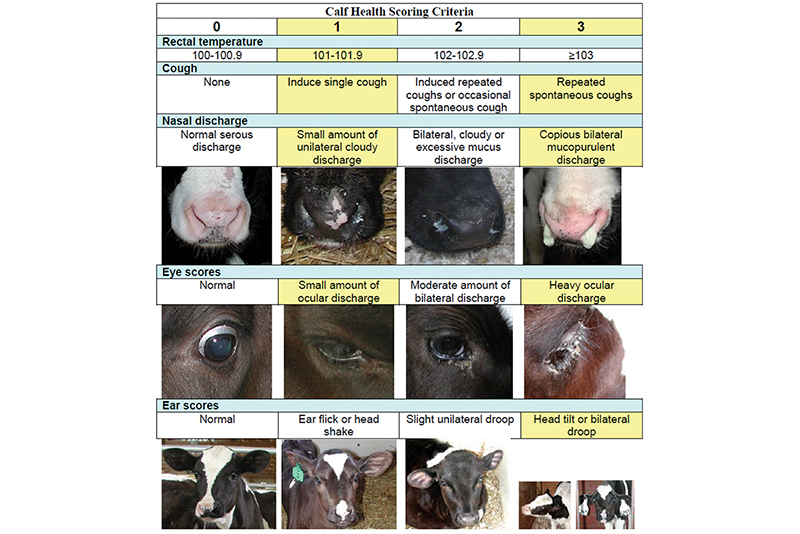

Calf Health Scoring Chart

This is an essential tool when managing calf health. In addition to assessing calf health, it is important to record these health events. This example comes from the University of Wisconsin – Madison. Courtesy Photo: University of Wisconsin – Madison

By Jakob Vogel B.Sc (Agr.)

AgriNews Contributor

In honour of this year’s construction edition of the AgriNews, we will be tackling the hot topic of calf rearing. Fortunately, the solutions facing correct calf rearing are virtually limitless. The options can be easily divided into three main categories: 1) Building new, 2) Retrofitting/alterations, or 3) having replacement animals raised by another producer as a “custom” option.

When beginning a new construction venture, you should first be asking yourself “Why am I looking into this?” In other words, what is the goal or objective that will deem this venture a success? Although the goal of every farm is different, often projects such as these are tied to either a financial or labour efficiency issue (gain). Speaking plainly, a choice must be made to properly invest capital and show an adequate return. Once a goal has been set for the new project, we must first determine what the status of the herd is. Consider that current calf rearing practices include a 10 per cent average mortality rate prior to weaning and a 20 per cent average morbidity rate at the same time-period. Will the goal be to decrease the number of heifers needed by 50 per cent? To ensure that the project comes to fruition successfully, solid and attainable goals must be established. Once solid goals are accepted, the adventure of further assessments can begin!

We must then assess and review what the current practices in place are, including all management and environmental constraints. Regardless of the actual age of the calf rearing facility, it is possible to make some changes to improve the performance on the farm. For example, can we increase meal frequency? Can we increase bedding type, amount and frequency? Can we improve the hygiene of the pens or hutches? Can we add fans to improve air quality in the summer and winter months?

During the assessment phase, it is recommended to use some type of calf health score card (as seen in Figure 1). Although this type of management tool can and should be incorporated in all calf facilities (especially when working with inexperienced employees), it becomes imperative when starting the benchmarking process.

With these questions in mind, many improvements can be made without the need to invest in a new facility, which may (depending on current situation) be a hard sell to the bank. Such subtle improvements may also include the purchase of an automated calf feeder, which can easily reduce labour needs associated with feeding calves, allowing more time in managing other environmental factors such as bedding and health monitoring protocols. Pre-existing facilities certainly may come with their fair share of inconveniences, such as supporting beams in unfortunate placings or poor ventilation. However, many of these things have the potential to become opportunities if you are willing to be flexible. For example, poor lighting in the old section of the barn can be managed by adding higher power LED lights, ventilation issues can be addressed by adding fans in the correct places, and cold barns can be managed by increasing the number of feedings and using clean, dry calf jackets during the challenging winter months.

In many situations, the renovation of a current calf rearing facility (or nursery) can be an opportunity to think outside the box and involve the different players on your farm management team. Sometimes, the hardest concept to visualize is maintaining or incorporating clean fresh air that has not gone through the remaining part of the barn (through the dairy herd specifically) to the calves. Although this may seem simple, a quick and easy solution may be to fabricate half walls with plastic to create a perfect micro-environment for calves.

Depending on the situation at the farm, the best option may also be to raise heifers off the farm, in the case of a custom feeder. On many farms in the US, this is a common practice, and the custom housing is not always next door, let alone in the same state! Although this option may come across as an additional expense, the validity and seriousness of the option should be considered. If we go back to the earlier example of the farm with 10 per cent mortality and 20 per cent morbidity rate prior to weaning, this can easily translate into significant losses for the farm. If we consider the above-mentioned farm is milking 100 cows with a 30 per cent turnover rate at an average age at first calving of 24 months, the farm should be targeting roughly 66 replacements per year (due to increased mortality rate prior to weaning). Additionally, studies conducted by Zoetis US have indicated that the treatment cost for a calf suffering from respiratory illness is roughly $26/case (including labour and medicine). Now, if the producer can partner with a reliable and successful custom feeder, the number of replacement heifers needed could decrease to 62 (including a 3% mortality rate) and improved morbidity rate (10% for this example) this represents a direct savings of roughly $333 for the producer. This example does not account for the total rearing costs or the improved lifetime performance that may be expected from healthy calves, but it is certainly something that should be kept in mind.

For producers that are able and willing to build a new facility to improve their calf rearing performances, common points for any building must be considered and evaluated. When planning a new build designed for calves, there are some important yet seemingly trivial points that can help prevent issues later.

The first point is to (when possible) ensure that alley scrappers are moving from the youngest pen toward the oldest. This will reduce the transmission of pathogens found in manure; notably Treponema sp. (most commonly associated with causing strawberry foot rot).

The second point would be to assess and install stalls (if used) of correct dimensions for the animals that are being housed. This will facilitate the heifers’ learning curve and encourage them to use the stalls rather than rest in the dirty alleys.

The third and final point is to reduce dead ends and ensure that two (clean) water points are accessible in each group of heifers so that both dominant and subordinate animals can have access to water. Going hand in hand with water, should be to allow for all heifers in a pen to have access to fresh feed at one time. Limiting feed access naturally hinders growth rates and thus impacts future performance and our ability to achieve the reproductive goals for replacement animals.

A recent survey of Quebec dairy farms shows the cost of rearing one animal on the average dairy farm (including both fixed and variable costs) now ranges between $3,500 and $3,700. This is a significant increase from the $2,000 – $2,500 benchmark that producers and consultants alike accepted all of five years ago. Although, with many producers successfully reducing the number of replacements being reared on farm, many farms can continue to improve their financial stability by decreasing the rate of involuntary culling or decreasing the rate of culling well-performing, high producing cows simply to make room for a less efficient heifer that will be transitioning shortly. Keeping this in mind, replacement animals should always be considered as an investment. To maintain progress on the dairy farm, hard and fast decisions must be made to reduce unnecessary expenses and improve the return on investments for every heifer that is reared.